Powder coating

Powder coating is the top choice for many projects because it’s durable, versatile, eco-friendly, improves appearance, and provides long-lasting protection.

Here’s just a few reasons to use Powder Coating:

Powder coat makes a hard, durable finish that resists chips, scratches, and wear better than most liquid paints, making it great for parts that get handled, hit, or used often

It forms a continuous protective layer that helps stop rust and corrosion, extending the life of metal parts indoors and out

Many powders are designed for outdoor use and resist fading, chalking, and sun damage, keeping parts looking newer longer

Powder cures into a smooth, even film without runs or sags and gives consistent coverage on complex shapes, edges, and hard-to-reach spots

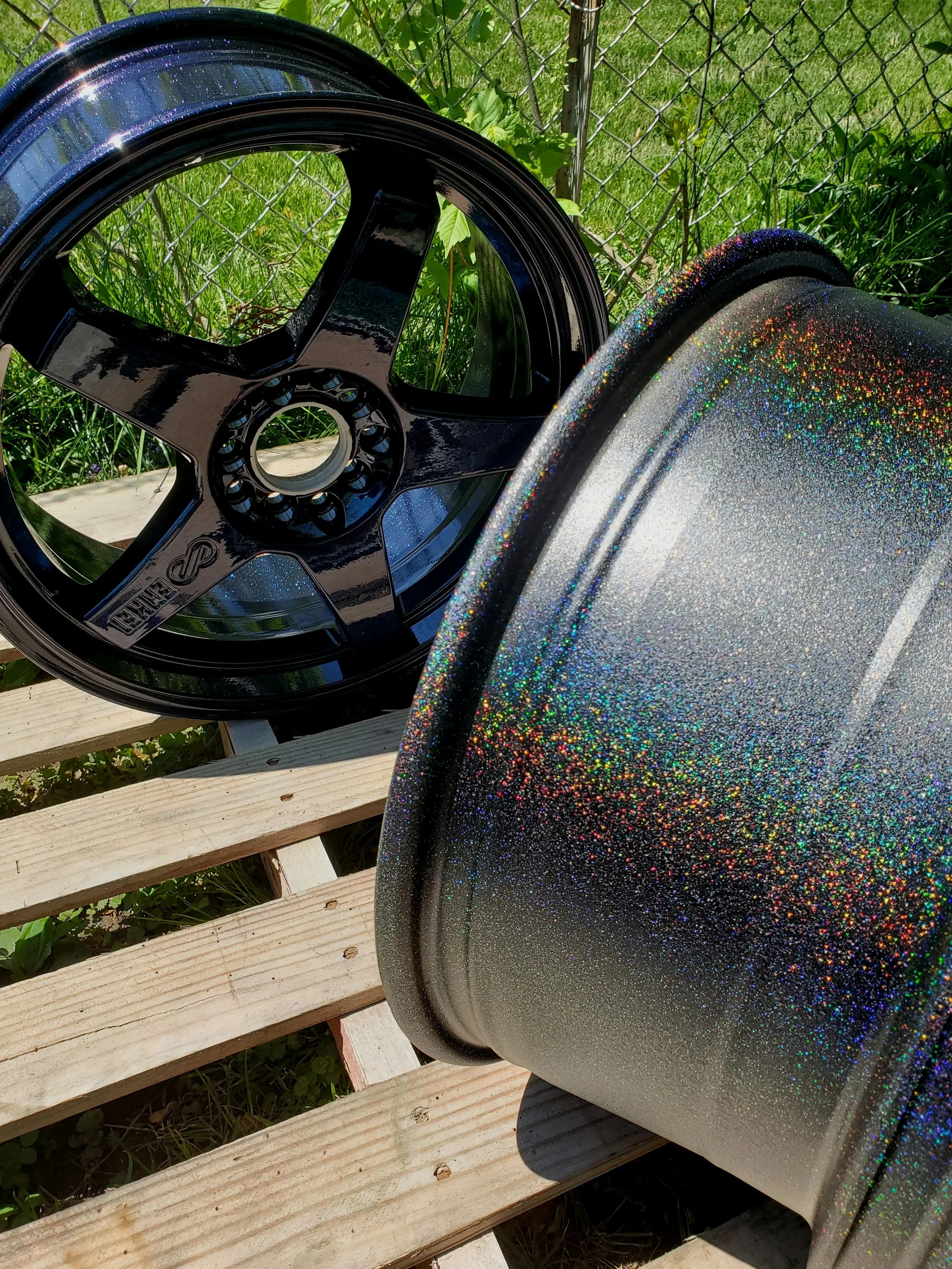

Available in many colors, textures, and gloss levels—matte, satin, gloss, wrinkle, metallic, and textured—so you can match looks and function

Powder coatings have lower VOCs (Volatile Organic Compounds) than many liquid paints, and overspray can often be reclaimed, reducing waste

They’re cost-effective for small and large runs; fast curing and less touch-up cut labor and turnaround time

Many powders resist chemicals, oils, and solvents better than conventional paints, useful when parts face cleaning or chemical exposure

Powder can build thicker protective films in one coat without sagging and improving protection without extra steps